Teadit® Products

Our product lineup features industry-proven sealing solutions from Teadit®. Whether you’re battling extreme temperatures, aggressive chemicals, or fugitive emissions, we have the gasket that delivers.

Featured Products:

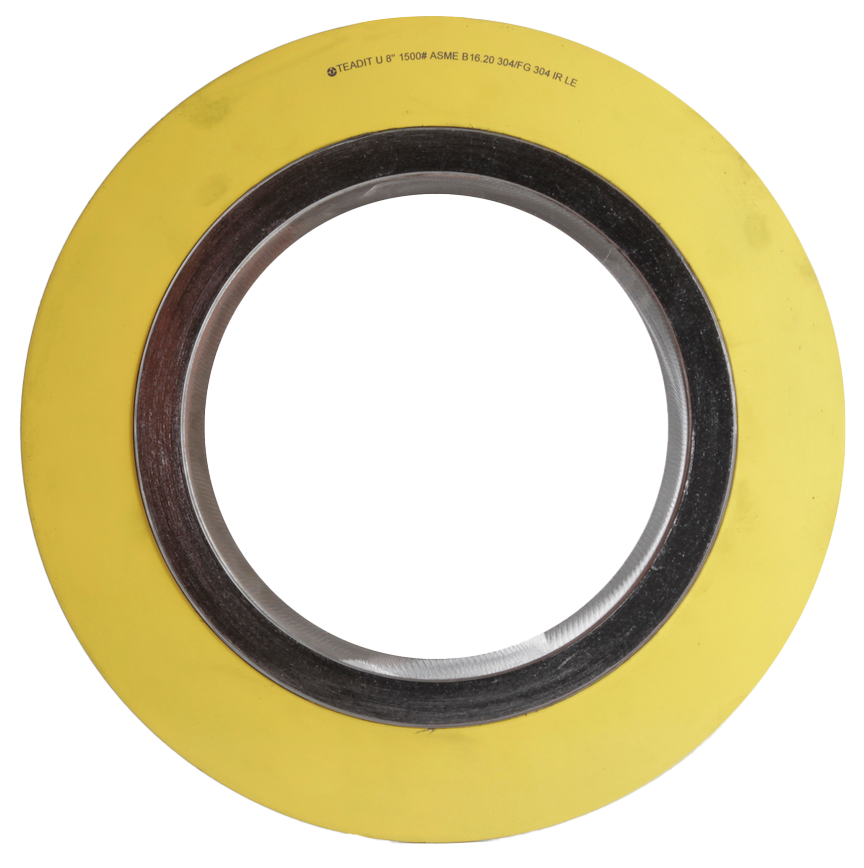

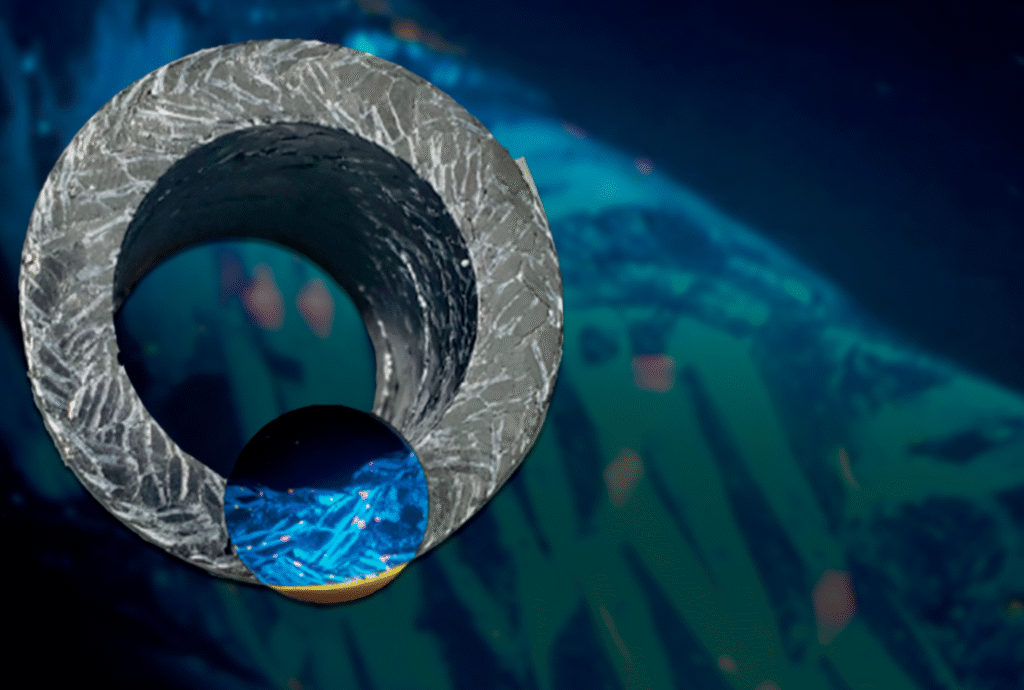

Teadit 913M

Graphite sheet gasket for steam, thermal fluids, and chemical service.

Description and Applications:

The 913M is the standard spiral wound gasket with an inner ring. The purpose of this ring is to fill out the space between the flanges, avoiding turbulence in the flow of the fluid or as protection against corrosion or erosion. It is also used as a compression limit. Gaskets with PTFE filler have a tendency to inward buckle thus the use of an inner ring is required by ASME B16.20. Inner rings are also required with ASME standard spiral wound gaskets with flexible graphite fillers unless the purchaser specifies otherwise and some sizes and pressure class require inner rings regardless of filler material.

Teadit Origin™ RC510

Low-E certified gasket, ideal for emissions control

Description and Applications:

Teadit® Origin™ RC510 is designed specifically for Rail Car Manway Dome Lid applications. It is a restructured hollow glass micro spheres filled PTFE gasket, manufactured utilizing Teadit’s unique Origin™ process technology. This provides excellent torque retention, high sealability and extended gasket life over multiple cycles. It is user friendly, and overcomes the problems of installation and removal associated with gaskets that are molded or produced from sheet materials.

The Origin™ RC510 is most robust, allowing for long-life in service. Rigorous evaluations have yielded results that show performance at a multitude of levels that are better than any rail car gasket in the market. There is nothing else like it.

Teadit Style 2000

Expanded PTFE gasket sheet for universal chemical resistance

Description and Applications:

Style 2000 packing is manufactured from high purity flexible graphite that is expanded and formed into a braidable yarn and then braided without binders or wire reinforcement. The finished product retains all the inherent benefits of flexible graphite: heat resistance, chemical inertness, low friction, self lubrication, and ready conformability.

The outstanding properties of this style make it a truly multi-service packing capable of a wide variety of uses throughout a plant. This style may be used in valves, pumps, expansion joints, mixers and agitators in the hostile environments of hydrocarbon processing, pulp and paper, power generation, metal-working and other industries where effective sealing is vital.

Teadit 2848

Low-emission valve packing

Description and Applications:

Teadit® 2848 is braided from a proprietary yarn made from flexible graphite reinforced with an innovative polymeric structure. This design allows the packing to meet the strict fugitive emissions service requirements without the need for metallic reinforcements, commonly used on this type of service. Each yarn is embedded with Teadit® Tags in its polymeric structure that are inseparable from the packing and create a uniquely identifiable fingerprint.

Teadit® Tags allow Teadit® 2848 to be identified in any situation – even when both packing and valve tags are lost! This unique fingerprint avoids warranty claim complications that often emerge from wrong product identification. Thanks to the polymeric reinforcement mesh that replaces the usual metallic material, this packing style leads to lower friction. This further improves control valve accuracy and allows for valves with smaller actuators (or handwheels).

Teadit® 2848 is a Low-Emissions packing designed for control and isolating valves alike. For control valves, it has proven performance on ISO 15848-1 most stringent test procedure, CC3. The packing maintained less than 2 ppm leakage even after 100,000 mechanical cycles and 4 thermal cycles. As for isolating valves, it has achieved success on API 622 3rd edition, with a leakage below 2 ppm even after 1,510 mechanical cycles and 5 thermal cycles.

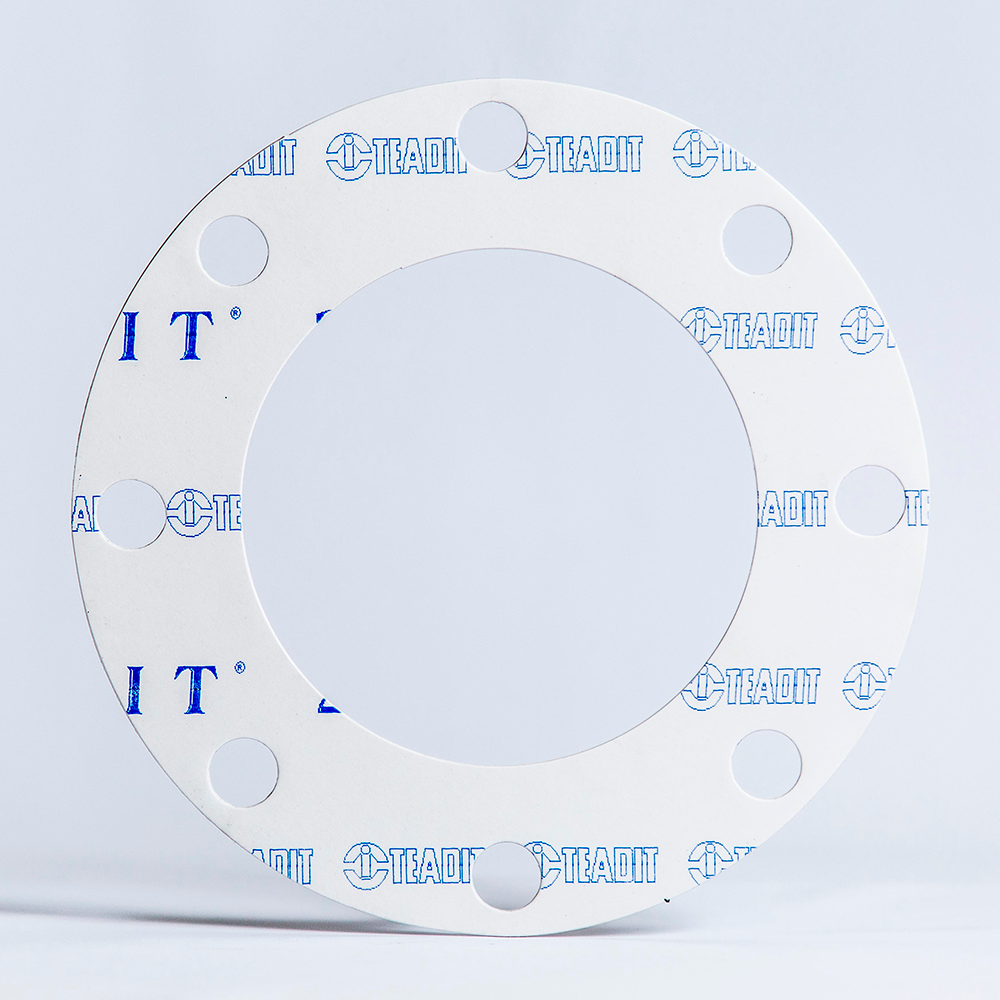

Teadit 24SH Gasket Sheet

FDA-compliant PTFE gasket sheet for food and pharma

Description and Applications:

TEADIT® 24SH is a large gasket sheet produced from 100% pure, multi-directionally expanded PTFE.

Universally employable gasket sheet for all applications. It is suitable for all types of flanges, nearly all media, a wide temperature range and for applications with the toughest demands on purity. It is inherently clean and non-toxic.

Gaskets of multi-directionally expanded PTFE have exceptional mechanical strength which allows operation with minimal creep at elevated temperatures.

The excellent malleability of TEADIT® 24SH makes repairing small damage and/or irregularities of the sealing area (flange surface) unnecessary.

Gaskets cut from TEADIT® 24SH are dimensionally stable, i. e. they do not get wider when compressed. This allows narrow flange faces to be sealed safely.

TEADIT® 24SH is quick and simple to install. The used gasket can be removed easily and without residue.

Approvals

TA-Luft / Blow-Out-Test VDI 2200 / FDA / USP Plastic Class VI / WRc / BAM / AREVA